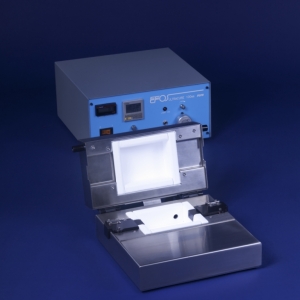

Revolutionary Solution for UV Curing Adhesives

A revolutionary solution for UV curing of adhesives, that bond balloons, hubs, and other components to catheters. The patented technology allows for fast, uniform cure, resulting in uniform and complete bonding in seconds. The MiniCure3D enables the bonding of multiple parts or joints simultaneously without needing to reposition the parts, streamlining the bonding process.

Lowers Costs Increases Yield

The MiniCure3D gives seamless production and adaptability for various product configurations. The incorporated UV LED source eliminates the need for external lamps that degrade over time, requiring frequent intensity checks and service. The patented technology allows enhanced process controls such as UV dose control, guaranteeing that each part receives the same dosage every time. This results in significantly lower production costs and downtime, greatly improving your production throughput for all of your adhesive bonding applications.

MiniCure3D Advantages

- Full 360° uniform adhesive or coating cure in as little as 5 seconds

- Uniform, 360° high-performance adhesion

- Product is bathed in uniform UV light — no rotation or motion required

- Product stays cool — uniformity means no over-curing

- Uses single pole light guide; no multiple pole guides to balance, wear out and replace

- Use either arc lamp or LED spot cure UV source

- Compatible with all popular spot cure UV sources and light guides, including fiber and liquid filled

- Repeatable, reliable and stable — fewer operator error opportunities

- Secure bushings facilitate product positioning

- Holds assembly for dispensing and curing

- Sized for variety of catheters; custom sizes available

- Easy to clean — just wipe with water or alcohol

- Inherently safe — no open-framed jigs needed

MiniCure3D-4E

- LCD touch screen controller

- Pre-set UV exposure for your part

- Set optimal UV dose (J/cm2)

- Or set UV exposure time (W/cm2)

- Sensor measures actual UV dose delivered to part, not light exiting light guide

- Dependable, repeatable UV dose control for every UV treated part

- Low UV alarm warns of lamp problem, prevents improper exposure

- Start/stop operation with foot switch or touch screen

- Chamber safety interlock prevents UV light operation when lid is open

MiniCure3D-4L

- Similar to MiniCure3D-4E with integral LED UV source

- Choose 365nm or 395nm source, or mixed source

- High power – 15W to 20W UV input to chamber

- No spot cure lamp or light guide needed

MiniCure3D-9E

- Similar to MiniCure3D-4E, with 9″ chamber – perfect for longer or larger parts

- Operates in horizontal or vertical orientation

- Uses either 1 or 2 spot cure UV lamps

- Universal light guide ports

MiniCure3D-9L

- Similar to MiniCure3D-9E with integral LED UV source

- Choose 365nm or 395nm source, or mixed source

- High power – 15W to 20W UV input to chamber

- No spot cure lamp or light guide needed

MiniCure3D-4B

- Start/stop operation using UV light source or foot pedal

- Lamp timer controls exposure time

- Chamber safety interlock prevents UV light operation when lid is open