Ideal applications for Vela Technology’s 3D UV curing technology commonly have one or more of the following characteristics:

- Complex shapes that would otherwise require multiple UV source locations or part manipulation

- Require uniform UV dose to meet quality specs

- Have multiple sites that require UV curing

- Heat sensitive

- Higher value parts that are painful to scrap

- High capacity, short cycle time required

- Need for high reliability, repeatability, minimal lamp changes, etc.

Medical Devices

Catheters (PTA and urinary, any length), guidewires, introducers, adhesive bonding of catheter attachments, bonding polymer parts, other medical device applications.

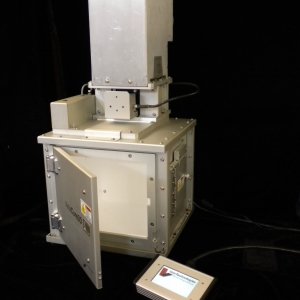

Catheters and Guidewires

Vela has made scores of catheter and guidewire coating curing systems for the big names in the industry, operating worldwide. Device manufacturers who convert to our technology never return to old-fashioned curing technology:

- Unmatched curing uniformity, which results in less scrap, lower surface stress areas, less particulate shedding

- High capacity and high throughput, up to hundreds of catheters in one curing run

- Cycle time in seconds

- Ability to specify/program UV dose (Joules/cm2) that is accurately delivered to each part

- No frequent lamp changes, part rotation, difficult loading and unloading

Adhesive Bonding

Vela is able to surround complex parts with diffuse UV, such that UV rays come to the part from every possible direction. This has significant advantages over essentially parallel UV rays reaching bondlines from light guides or lamps mounted over conveyors:

- Multiple adhesive application sites can be cured in a single cycle

- Adequate UV reaches difficult-to-reach sites to achieve reliable cure without lamp or part manipulation

- Repeatable, measured dose application gives higher quality, less scrap, zero leakers

- Fast

Coated Tube, Wire & Cable Curing

- Uniform cure – able to achieve cure to spec without over-curing some areas

- Efficient UV coupling to product reduces need for UV lamps, reduces heat, ventilation and energy cost

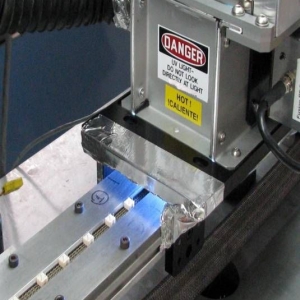

Electronics

- Diffuse UV is able to reach difficult-to-cure areas, reducing heat delivered to sensitive components

- No lamp or part manipulation/rotation

- No “out of focus” areas on boards or parts

Other Applications

Vela has worked with manufacturers of many different products – hearing aids, optics, lenses, potting and filling, and more. Bring us your most difficult problems!